|

ENVIRONMENTAL REPORT 2017

ENVIRONMENT | ||||

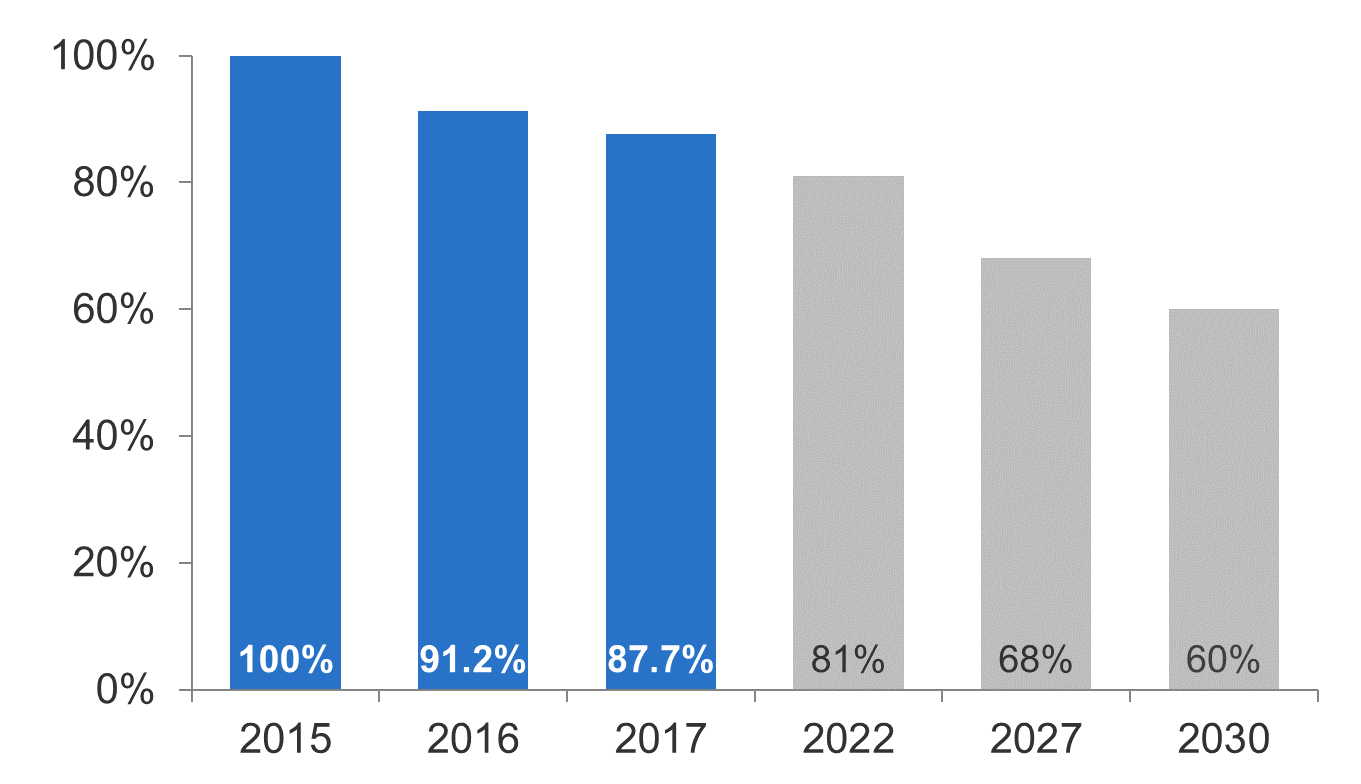

| | DECLARATION ON CLIMATE ISSUESMore than ever before, people now realize the negative impact that the use of fossil fuels has on nature. Its use has resulted in global warming, ozone-layer depletion and acid rain. For decades, the United Nations have been leading an international, consensual program to set goals for sustainable development and combat climate change. By doing so, they provide the necessary framework for all communities, large and small, to take action. A vital part of that program was the Session of the Conference of the Parties to the United Nations Framework Convention on Climate Change, otherwise known as Paris 2015, or COP21, with the aim of keeping global warming below 2°C. For Iceland, which bases large part of its economic foundation on harvesting natural resources from the ocean in a sustainable way, the changes associated with global warming and pollution of the ocean leave all the key components of its modern economy utterly exposed, in addition to threatening the quality of life for future generations. To support global and local environmental initiatives, Eimskip signed the Reykjavík Declaration on Climate Issues in November 2015. The agreement includes reducing greenhouse gas emission, reducing waste and monitoring the results of the measures and regularly publicizing the information. Eimskip decided to use advanced software technology together with change management to enable the Company to meet future environmental challenges related to environmental compliance, energy and waste efficiency and information sharing. The Company’s environmental management solution is a digital data collection and environmental compliance solution, covering energy and waste management of vessel fleet, truck fleet, terminal assets, warehouses and office space. The solution is based on a digital platform technology, connecting the Company digitally to its supply chain and to its customers. The company Klappir Green Solutions hf. works with Eimskip on environmental management and certifies its environmental management solution. As an environmental service to its customers, Eimskip has developed a carbon calculator for both sea and land transport. The carbon calculator and the Company’s Environmental Report are accessible on its website. Eimskip will continue focusing on reduced emissions and improved waste disposal and, at the same time, increase the transparency of its ecological footprint throughout the supply chain. The focus in 2018 will be on continued monitoring of emissions and waste from the supply chain by collecting electronic data from all emitting sources and streaming it automatically to a common data warehouse. Digitalization of emission and waste-registration data from the supply chain enables continuous monitoring of measures and provides reliable and transparent information on the status. In January 2017, Eimskip signed a contract with a shipyard in China on building two 2,150 TEU ice class Polar Code container vessels with expected delivery in the middle of 2019. These vessels are built in line with environmental standards and are designed to be fuel-efficient. CARBON FOOTPRINTEimskip defines its ecological footprint as a combination of carbon footprint and waste disposal. The operation of the Company’s vessels is the main contributor to its carbon footprint. The Company respects the environment and recognizes the effects that climate change could have on society and its business activities and the need for a low-carbon economy. Minimization of the environmental load from its operations focuses on achieving full clarity regarding emissions and waste from each of the emitting sources in the supply chain. To make this possible, use of data and analytics was stepped up in 2016 and further developed in 2017, giving Eimskip a better overview of its ecological footprint and reduction opportunities. The Company’s environmental management system is linked to all major assets in its supply chain, streaming reliable and transparent information on its environmental matters. The calculation of the Company’s carbon footprint is presented in the graph below, which shows accumulated results of carbon intensity per ton of transported units, compared to the base year 2015. CARBON INTENSITY PER TON OF TRANSPORTED UNITS

The accumulated reduction of Eimskip’s carbon footprint in the years 2016 and 2017 was 12.3% compared to the base year 2015, calculated per ton of transported units. The Company’s aim is to further reduce its footprint in the coming years, with a goal of 19% accumulated reduction in 2022 compared to the base year 2015, 32% in 2027 and 40% accumulated reduction in 2030. This goal of total reduction is comparable with Iceland’s decision of joining the European Union and Norway in their common goal of 40% reduction of emission in 2030. | |||

ENVIRONMENTAL POLICY AND AIMS | ||||

In 1991, Eimskip became one of the first companies in Iceland to establish an environmental policy as a main driver for actions for improved ecological footprint. Since then, the challenges in this field have developed very quickly and the transportation industry, as well as others, realizes how important environmental issues are for the world today.

Eimskip has the following environmental aims:

Identify and control potential environmental risks posed by the Company’s operationsAll the Company’s vessels are run according to a certified Safety Management System complying with the ISM (International Safety Management) code. This includes risk assessments with regard to environmental risks and applicable procedures to control and prevent environmental risks as far as possible. It also includes emergency procedures for each vessel and the office to ensure proper response to incidents that potentially could harm the environment. Eimskip operates a loss prevention team. One of its tasks is to monitor and identify potential environmental risks anywhere inside the Company and its operations and to highlight them to the applicable managers and/or employees. Manage the Company’s operations according to applicable laws, regulations and international conventionsNew rules came into effect on 1 January 2015 regarding sulphur emissions from vessels in Emission Control Areas (ECA). The rules oblige shipping companies to use fuel with a sulphur content of no more than 0.1% inside these areas, a reduction from the earlier limit of 1.0%. These new rules apply to the majority of Eimskip’s sailing routes. Eimskip’s ambition is to be a leading transportation company in the North Atlantic and a leader in responsibly fulfilling global environmental requirements. The new ECA regulation is intended to have positive effects on the environment, as the goal is to reduce the sulphur emissions of vessels in the ECA zones by 90%. In 2017, the Company worked on implementation of digital Monitoring, Reporting and Verification (MRV) and received a certification at year-end. Recycle waste from the Company’s operations and minimize the creation of wasteFor many years, Eimskip has categorized and recycled the majority of waste from its operations. In recent years, special focus has been set on recycling waste as far as possible, and this will continue. According to MARPOL Annex V, all vessels are to have a garbage management plan and a garbage record book. To further improve the monitoring, recycling and reporting, Eimskip digitized the garbage log and started streaming the data to the environmental data warehouse in 2016. The solution was further developed in 2017, with digitalization of MARPOL Annex I and MARPOL Annex VI. Through this, waste has become a part of the supply chain footprint calculation and analytics. This also increases the possibility of further creating value from the waste. Improve energy efficiency of the Company’s vesselsAs a front-runner in the industry, Eimskip started to explore the use of new energy management technologies in 2005 with the intention of increasing the energy efficiency of its fleet. Energy management solutions in shipping were new at that time and the technology was in its infancy. Today, energy efficiency is an integrated part of the operation of the vessel fleet. Based on the positive results, Eimskip will continue focusing on improved energy efficiency and decreased environmental impact of its vessels. Improve energy efficiency of the Company’s fleet of trucks and other equipmentEimskip owns a majority share in European Transport Services B.V., a trucking company located in the Netherlands that specializes in reefer container haulage with a fleet of approximately 20 trucks. The majority of these are equipped with a TRS system, an environmentally friendly transport refrigeration system where the engine of the truck provides power to the reefer container, resulting in much lower emissions than the conventional generators used to power reefer containers’ refrigeration equipment. Eimskip operates about 140 trucks in Iceland, which are connected to a monitoring system for improved energy efficiency. The Company operates mobile harbor cranes connected directly to external electrical power at two of the Company’s terminals in Iceland: Reykjavík and Reydarfjördur on the east coast. They are from Gottwald and were originally designed to be able to run either on diesel engines or by being connected to an external, electrical power supply. The cranes use 1.2 MW power at 11 KV, which is similar to the requirements of a village of 500 to 700 inhabitants. Their operation is environmentally friendly since they produce no emissions when running on electrical power. By operating cranes with electricity, Eimskip reduces carbon dioxide (CO2) by 340 metric tons per year. This amounts to what a 17-hectare forest is able to bind on an annual basis. In addition, pollution from noise and dust is reduced at the terminals. Five harbor cranes were taken into operation 2015 to 2017 and three of them are fitted for an external, electrical power supply. Work on savings and improving efficiency in energy consumption on the Company’s premisesMost of the Company’s premises and storage facilities use electricity for lighting and operation of refrigeration systems and electrical loading stations. The harbor lighting also consumes electrical power. The focus of 2016 and 2017 was to obtain a full transparency regarding electrical power consumption and its distribution between various consumption units by streaming power data into the environmental database for analytical purposes, the aim being a further reduction of energy use. Set yearly goals on environmental issuesIn 2015, Eimskip decided to take a vast step forward in improving its overview of its ecological footprint by implementing its own electronic Environmental Management System using data analytics and connectivity solutions. These allow the Company to link together various categories of data collected from the entire supply chain. Crews and office personnel are now provided with high quality information on environmental performance in a user-friendly format. Eimskip’s Environmental Management System utilizes the data collected from the various data sources in the supply chain. The system employs inbuilt predictive analytics, data preparation and user dashboards. This supports monitoring of the footprint throughout the supply chain, including all users, and indicates where improvements are needed. Data from the entire fleet is now streamed into one Company-designed data warehouse. Other emitters, including trucks and electrical power users, were also connected to the data warehouse in 2016. Provide employees and customers with regular training on environmental issuesTraining crew members has been a crucial part of implementing the energy management solutions on the Company’s vessels and has resulted in a strong teamwork with goals for each week of the year. Specific training sessions have been carried out on the vessels in using a Ship Energy Efficiency Management Plan (SEEMP) as a tool for efficiency improvement, in using the onboard energy management system and in working with fuel changeovers when sailing into ECA zones. The focus in 2018 is to continue training employees in improved handling of waste. | ||||

PERFORMANCE HIGHLIGHTS AND TARGETS | ||||

Initiatives | ||||

VesselsAs a front-runner in the industry, Eimskip started to explore the use of new energy management technologies in 2005 with the intention of increasing the energy efficiency of its fleet. Energy management solutions in shipping were new at that time and the technology was in its infancy. Today, energy efficiency is an integrated part of the operation of the vessel fleet. Based on the positive results, Eimskip will continue focusing on improved energy efficiency and decreased environmental impact of its vessels. The Company’s vessel operators’ mission is to further improve the energy efficiency of the vessels year by year. Training crew members has been a crucial part of implementing the energy management solutions on the Company’s vessels and has resulted in a strong teamwork with goals for each week of the year. Specific training sessions have been carried out on the vessels in using a Ship Energy Efficiency Management Plan (SEEMP) as a tool for efficiency improvement, in using the on-board energy management system and in working with fuel changeovers when sailing into ECA zones. Eimskip got the MRV Certificate for the fleet covered by the law in the end of December 2017. The focus in 2018 is to continue training employees in environmental management including energy- and waste management. The digital environmental software will be extended and will include all bunker orders. This will further improve the transparency of the data and ensure that all data from order to delivery will mach. | ||||

Trucks and CarsEimskip operates approximately 140 trucks in Iceland that are connected to a monitoring system for improved driving, safety and energy efficiency. The fleet management system is logging fuel-consumption data and position data of each truck in the fleet. The focus in 2017 was to get exact electronic data on the fuel filled by each truck to feed the environmental system with correct, transparent and solid data on the fuel filled at each time. Most of the trucks have now a special credit card that is linked to the truck registration number. When truck is filling fuel, the fuel data, truck registration number, location, time and card number is streamed to Eimskip’s environmental system. By this, all data is streamed directly from fuel pump to the environmental system. Also when renewing the truck fleet, the requirement for order is based on low fuel consumption and environmentally friendly built vehicles. In 2018, the fleet management system will be connected to the environmental system to get more environmental transparency of the truck fleet and of each truck in the fleet. Accordingly, truck emission goals will be set and followed in the same manner as on the Company’s vessels. | ||||

Port facilities and warehousesEimskip is operating a number of port facilities in Iceland. The Company’s main port facility is in Sundahöfn in Reykjavik. Three new harbor cranes were taken into operation in 2015 and 2016 and all of them are fitted for an external, electrical power supply. In Sundahöfn, Eimskip operates two mobile cranes for loading and unloading vessels. Both of these cranes will be operating on electricity in 2018. The Company also operates one gantry crane in Sundahöfn which is powered by electricity. In Reydarfjördur, the Company operates one similar mobile crane as in Sundahöfn, powered by electricity. In the port of Grundartangi, Eimskip operates the same type of crane that is currently being connected to electricity instead of burning gasoil. A working group consisting of people from Eimskip, Faxaflóahafnir and Hafid (Icelandic Center of Excellence for Sustainable Use and Conservation of the Ocean), is currently studying the feasibility to install electricity shore connections for vessels while calling the port of Reykjavík. | ||||